MAIN BUSINESS

Substrate material is the fundamental material for manufacturing semiconductor components and printed circuit boards. The packaging substrate is an important component of electronic packaging and serves as a bridge between chips and external circuits. High performance ceramic substrates are the most fundamental materials in the chip and electronic packaging industry.

MORESubstrate material is the fundamental material for manufacturing semiconductor components and printed circuit boards. The packaging substrate is an important component of electronic packaging and serves as a bridge between chips and external circuits. High performance ceramic substrates are the most fundamental materials in the chip and electronic packaging industry.

MOREFuzhou Ceravite New Materials Development Co.,Ltd.

ABOUT US

CERAVITE was founded in 2007 by professor Huang Xiangdong,professor Jiang Ming and Fuzhou University Asset Management Co., LTD. Professor Huang holds a PHD in Materials Sciencefrom Tsinghua University, and he is a teacher at the School of Materials, Fuzhou University. Professor Jiang is a professor at the School of Mechanical Engineering,FuzhouUniversity.CERAVITE is an innovative company of technology. Themain fields include research, development and production of new materials like non-oxideceramicmaterials,designand manufacture of vacuum hot-pressing furnace, and design and manufacture of hot-pressing mold.

MORE

Founded in

Product Style

Floor space

Cooperative clients

NEWS UPDATES

Why choose us

Our Advantages

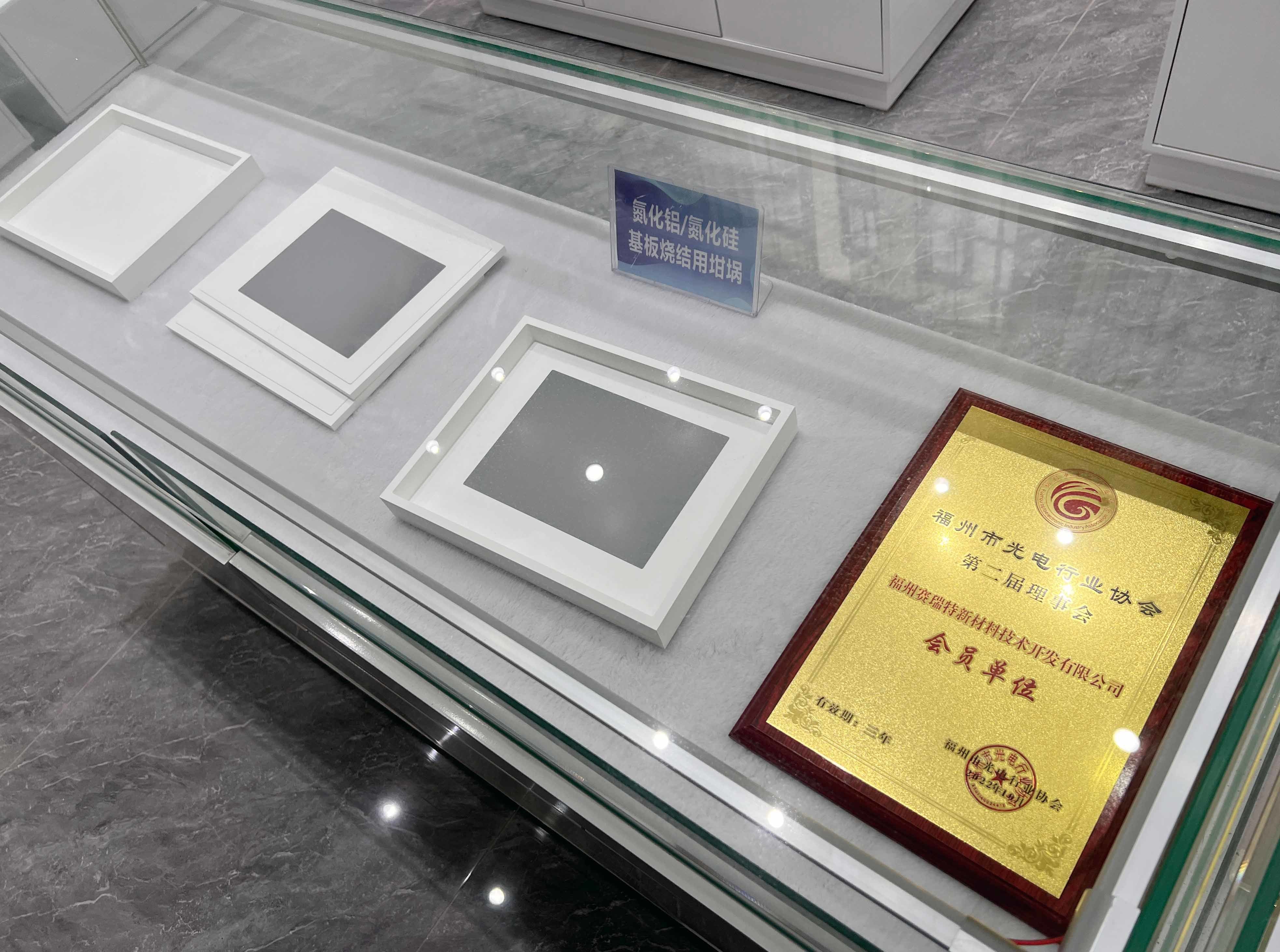

he company's main products are hot pressed boron nitride ceramics and hot pressed boron nitride composite ceramics. The company currently uses metal atomization nozzles for 3D printing; The pure boron nitride ceramic fixture products used for aluminum nitride and silicon nitride ceramic substrates are in a leading position both domestically and internationally.

Technical advantages

The maximum size of hot-pressed boron nitride and hot-pressed aluminum nitride that can be produced is 500 * 500mm, which is the largest size in China

QUALIFICATIONS

A technology innovative enterprise mainly engaged in the research, development, production, vacuum hot pressing design and manufacturing of new material products such as non oxide ceramics, and the design and manufacturing of hot pressing molds.

MORE

QR code

Fuzhou Ceravite New Materials Development Co.,Ltd.

Add:691 Dongtian Village, Yangxia Street, Fuqing City, Fuzhou City, Liandong U Valley·

Building 13 and 15 of Fuqing Rongqiao Economic and Technological Development Center

Tel:86-13799982018 (Mr. Chen)

E-mail: ccb@ceravite.com.cn

Tel: 86-0591-83709236

Fax: 86-0591-83709236