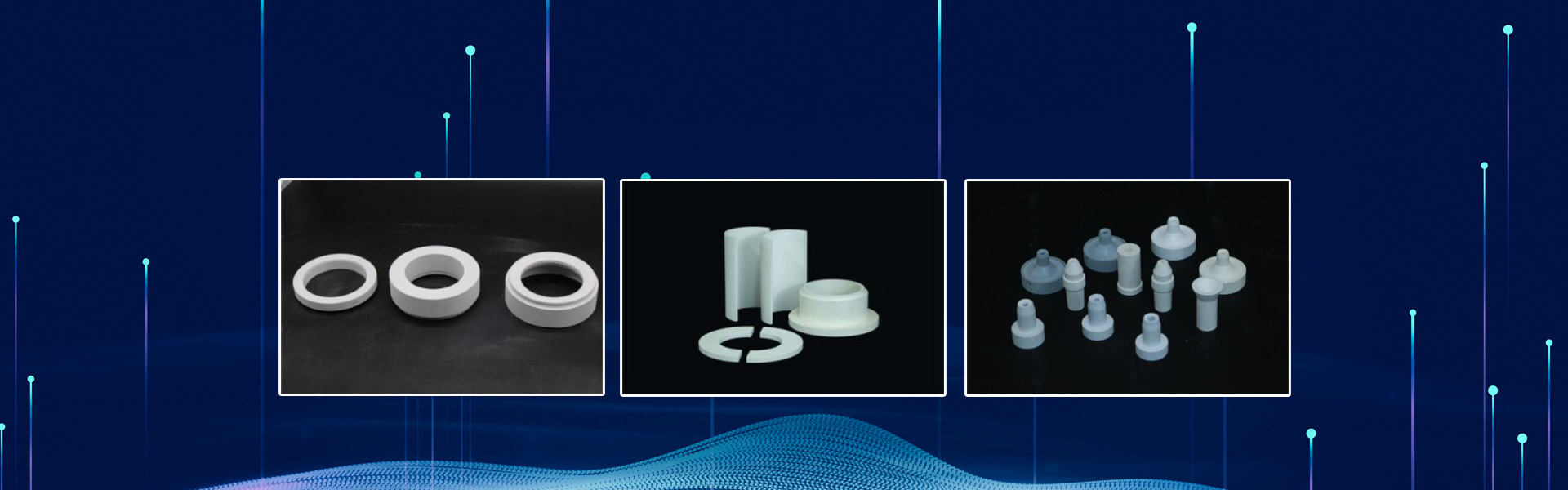

Metal atomization powder nozzle for 3D printing

In recent years, the additive manufacturing industry based on 3D printing technology has made rapid progress and has gained more and more applications in the production of special and complex components. The basic raw material for metal 3D printing technology is metal powder with high sphericity and narrow particle size distribution. The basic process for the preparation and production of this powder is to melt the metal alloy and flow out through a nozzle (leak). At the nozzle outlet, high-pressure airflow is used to atomize the metal liquid, while cooling it into spherical particles. The nozzle material needs to have properties such as high temperature resistance, heat shock resistance, fine machining ability, and resistance to metal liquid corrosion. The company entered this field in 2015 and has now become a highly influential and shipping company in the industry!

Nozzles for Gas Automized Powders Making

1.Excellent corrosion resistance and wear resistance,resistant to corrosion of stainless steel,copper, aluminum, iron silicon aluminum, iron silicon nickel, iron nickel and other allo 2.The highest using temperature is 1750℃, and the using life is long. 3. Strong thermal shock resistance, high temperature alloy solution instant repeated scouringwithout cracking and deformation. 4.The formula can be independently designed according to customer requirements.

1.The optimized formula and unique process make it highly resistant to thermal shock and high-temperature creep. Maximum using temperature 1700 ℃. 2.Low thermal expansion coefficient, no cracking or deformation during use. 3.Strong erosion resistance, wear resistance and metal corrosion resistance. Long service life. 4.Good raw materials, process control, product stability.

QR code

Fuzhou Ceravite New Materials Development Co.,Ltd.

Add:691 Dongtian Village, Yangxia Street, Fuqing City, Fuzhou City, Liandong U Valley·

Building 13 and 15 of Fuqing Rongqiao Economic and Technological Development Center

Tel:86-13799982018 (Mr. Chen)

E-mail: ccb@ceravite.com.cn

Tel: 86-0591-83709236

Fax: 86-0591-83709236