Thermal emission electronic components

Lanthanum hexaboride and cerium hexaboride are widely used in electron gun and other fields as high electron emissivity products. Currently in the stage of small-scale production. The product has received high praise from users.

Composite boron nitride heating plate, forming mold, etc

Replacing metal heating, it has fast heat transfer, no deformation, strong thermal shock resistance, and high usage temperature, up to 1700 degrees Celsius.

Hot pressed ceramic target material

Adopting processes such as hot isostatic pressing and hot pressing to produce ceramic targets with high melting points and difficulty in sintering. At present, the ceramic targets produced include high-purity and high-density products such as aluminum nitride, silicon nitride, boron nitride, lanthanum hexaborate, cerium hexaborate, titanium borate, boron carbide, etc.

Boron nitride belongs to the hexagonal system.Its structure is similar to graphite,and their properties are alsosimilar. Therefore, it is also called "white graphite". It has good heat resistance, thermal stability , thermal conductivity,high temperature dielectric strength, and is an ideal heat dissipating material and high temperature insulatingmaterial. Mohs hardness 2 can be processed into various shaped parts.

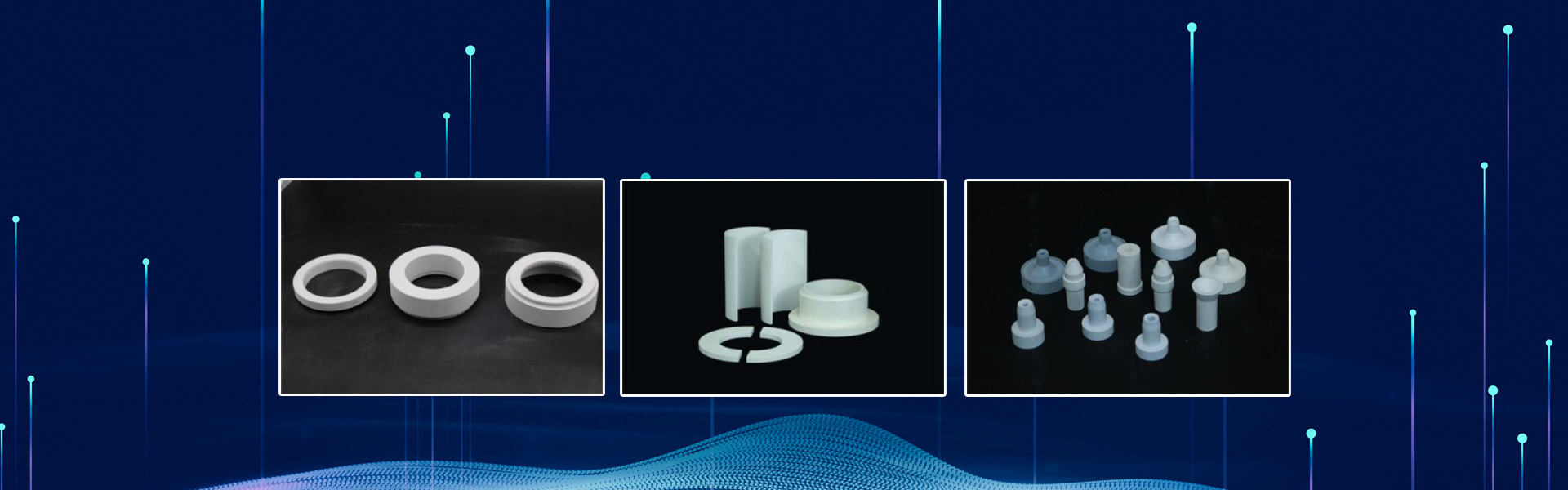

Nozzles for Gas Automized Powders Making

1.Excellent corrosion resistance and wear resistance,resistant to corrosion of stainless steel,copper, aluminum, iron silicon aluminum, iron silicon nickel, iron nickel and other allo 2.The highest using temperature is 1750℃, and the using life is long. 3. Strong thermal shock resistance, high temperature alloy solution instant repeated scouringwithout cracking and deformation. 4.The formula can be independently designed according to customer requirements.

1.The optimized formula and unique process make it highly resistant to thermal shock and high-temperature creep. Maximum using temperature 1700 ℃. 2.Low thermal expansion coefficient, no cracking or deformation during use. 3.Strong erosion resistance, wear resistance and metal corrosion resistance. Long service life. 4.Good raw materials, process control, product stability.

QR code

Fuzhou Ceravite New Materials Development Co.,Ltd.

Add:691 Dongtian Village, Yangxia Street, Fuqing City, Fuzhou City, Liandong U Valley·

Building 13 and 15 of Fuqing Rongqiao Economic and Technological Development Center

Tel:86-13799982018 (Mr. Chen)

E-mail: ccb@ceravite.com.cn

Tel: 86-0591-83709236

Fax: 86-0591-83709236